Incoloy 825 Forged Fittings

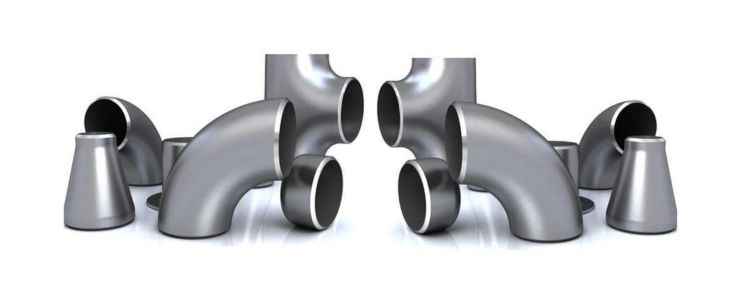

Arrow Piping Solutions is a prominent manufacturer and exporter of superior quality Incoloy 825 Forged Fittings in standard and customized sizes as per customer requirements. These fittings are made from a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium, offering excellent resistance to phosphoric and sulfuric acids, pitting, crevice corrosion, and intergranular corrosion.

We manufacture Incoloy 825 Forged Fittings using top-grade raw materials and advanced forging techniques. These fittings are known for their high mechanical strength, excellent surface finish, corrosion resistance, dimensional accuracy, and long service life. They are suitable for various harsh environments and demanding applications.

Incoloy 825 Forged Fittings Range:

- Alloy 825 Forged Coupling

- ASTM B564 Alloy 825 Threaded Union

- Alloy 825 Hex Bushing

- 825 Incoloy Socketweld 45° Elbow

- Incoloy 825 High Pressure Forged Pipe Fittings

- Incoloy 825 Plug

- Alloy 825 90° Socketweld Cross

- Incoloy 825 Screwed Half Coupling

- Incoloy Alloy 825 Threaded Elbow

- Incoloy 825 Socketweld Reducing Tee

- Incoloy 825 Threaded Cap

Specifications

| Specification | ASTM B564 / ASME SB564 |

|---|---|

| Dimension Standards | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size Range | 1/8" NB to 4" NB |

| Type | Socketweld, Screwed-Threaded (NPT/PT) |

| Pressure Rating | Threaded: 2000 / 3000 / 6000 LBS Socketweld: 3000 / 6000 / 9000 LBS |

Equivalent Grades

| Standard | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo |

Incoloy 825 Forged Fittings undergo all stages of the quality testing process under the inspection of our quality control team. We make sure to carry out all types of tests to ensure error-free and accuracy of the product. We provide all the test certificates and required documents to our customers. We guarantee to supply Forged Fittings having precise dimensions and specifications as per the national and international standards. Arrow Piping Solutions offers numerous ways of packaging and shipping to deliver damage to free products as per the demands of our valued clients.

Chemical Composition (%):

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Incoloy 825 | 0.05 max | 1.00 max | 0.50 max | 0.03 max | 1.50 – 3.00 | 22.00 | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 | 0.06 – 1.20 |

Mechanical Properties

| Density | 8.14 g/cm³ |

|---|---|

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | 550 MPa / 80,000 psi |

| Yield Strength (0.2% Offset) | 220 MPa / 32,000 psi |

| Elongation | 30% |

Manufacturing Standards

| ASTM B564 – ASME SB564 | Wrought Austenitic Stainless Steel Piping Fittings |

| ASME B16.9 | Factory-Made Wrought Buttwelding Fittings |

| ASME B16.11 | Socket Welding and Threaded Forged Fittings |

| MSS SP-43 | Low Pressure Corrosion Resistant Applications |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

| BS3799 | Screwed & Socket-welding Fittings for Petroleum Industry |

Applications of Incoloy 825 Forged Fittings

- Chemical Industry

- Petrochemical Industry

- Marine & Power Transmission

- Power Plants

- Energy Industries

- Pharmaceutical Processing

- Modern Architecture

- Home Appliances

- Water Waste Projects

- Synthetic Fiber Manufacturing

- Heat Exchangers

- Fluid Piping

- Dairy and Food Processing

- Furniture Industry

Arrow Piping Solutions ensures premium quality, cost-effective Incoloy 825 Forged Fittings with secure packaging, prompt delivery, and full certification. Get in touch with us today for competitive pricing and customized solutions for your industrial projects.